Considering the need of EN 15085-2:2007 (Railway Welding) Documentation Kit, and how consultants make huge money by selling the papers to organizations just changing the names in those documents instead of real services as expected from consultants, ISOFOLDER is a place where we are trying to make the system effective for documentation for any certification or compliance globally by providing pre-written documentation kit.

ABOUT BS EN 15085-2:2007

Railway applications. Welding of railway vehicles and components. Quality requirements and certification of welding manufacturer. This series of standards applies to welding of metallic materials in the manufacture and maintenance of railway vehicles and their parts. This part of the series defines the certification levels as well as the requirements for welding manufacturers and describes the procedure for the recognition of welding manufacturers.

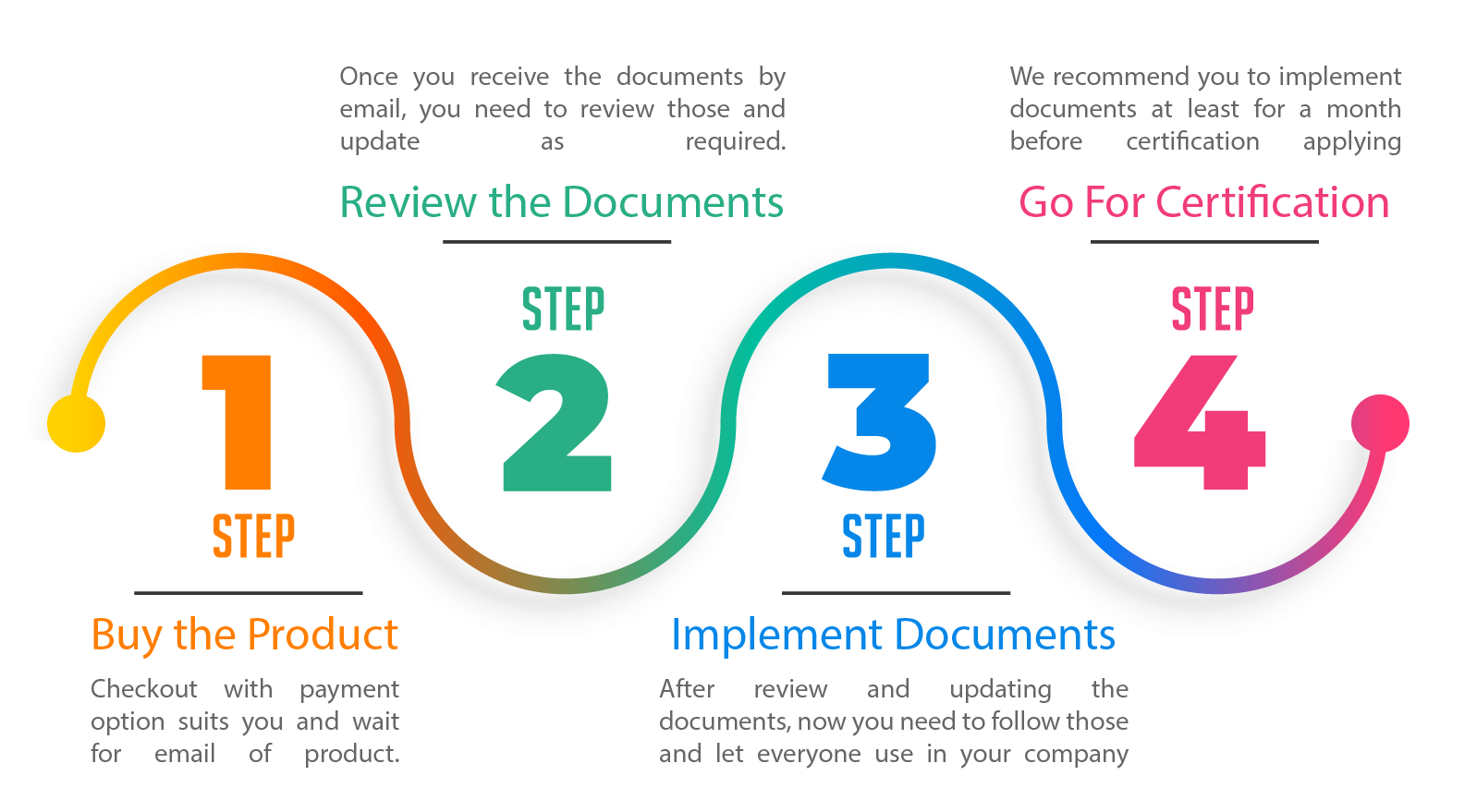

No Matter you are planning to get Certified based on international standards e.g. ISO 9001:2015, ISO 14001:2015 etc. or you are asked documentation for compliance e.g. pre-qualifying, legal compliance, tendering, etc. Our EN 15085-2:2007 (Railway Welding) Documentation Kit will facilitate you with less time and cheapest price.

Our EN 15085-2:2007 (Railway Welding) Documentation Kit is written in plain English to make easily customized by you without expertise in standards. We developed a documentation kit while making it user-friendly, easy to learn and time-saving.

We have added sample filled documents, comments of information to be added and other helping tools for you. We are available for lifetime support via email for helping you to make a documentation kit that works for you.

Contents of Documentation Kit

EN 15085-2:2007 (Railway Welding) Documentation Kit is designed in following documents

- EN 15085 Manual: A sample copy of railway welding manual which meets the requirements for EN 15085 certification of railway welding manufacturer for welding of railway vehicle and components. The manual document includes quality policy, scope, review requirements, technical review, and organization structure as well as macro level system for technical requirements.

- Welding Procedures: 04 mandatory Procedure for control of welding consumables that help the organization to make the best system and quick process improvements.

- Job Description: It gives specific rules and responsibilities of different personnel engaged in the welding certification.

- Inspection & Test Plan: It includes 01 sample copy of inspection & test plan that covers detail ideas for process implementation and improvements.

- Sample Blank Forms: Set of the total of 22 blank formats required to maintain records as well as establish control and make system in the organization.

We have added many documents for reference and use, however, you can add any additional document which is not part of our documentation kit, or can ignore those document which is not applicable to your activities from our documentation kit.

Documentation kit contains A Manual that addresses clause wise details for how management system are designed and implemented in your organization.

A set of procedures, as following, which helps you to manage your operations and address requirements of management system through the implementation of procedures.

- Procedure for Control of Welding Consumable

- Procedure for Visual Testing

- Procedure for Welding Repair

- Procedure for Preparation & Control of Welding Document

A set of Formats, as the following, which is actually used to implement the system and keep records to provide evidence of the fulfillment of standard requirements.

- Requirement Review Of Parts

- Vendor Approval Form

- Production Planning

- Route History Card

- Welding log Book

- Incoming Material Inspection Report

- Fit Up Report

- Calibration Status of Instrument/ Equipment

- Qualified Welder list

- Preventive Maintenance Check Point

- Preventive Maintenance Schedule-Welding

- Technical Review Of Parts

- Sub Contract Audit Report

- Part History Card

- Assembly Card

- Disposable of Non Conforming Product

- Welding Consumable Inspection Report

- Visual inspection Report

- Dimension Inspection Report

- WPS List

- Equipment History Card

- Equipment Wise Preventive Maintenance

- Check Point

Documentation Kit

Documentation Kit Training Material

Training Material Self-Paced Trainings

Self-Paced Trainings

Reviews

Clear filtersThere are no reviews yet.